| |

Agricultural tools and implements

|

| |

The University has developed so far 20 agricultural tools and implements suitable for different farming situations of the Konkan regio |

| |

1) Vaibhav Sickle |

|

|

A hand tool with serrated self-sharpening blade to harvest rice, close to soil surface

|

|

Helps to reduce stem borer pest intensity. |

|

Saving in labour requirement : 12 to 20 mandays/ ha |

|

|

| |

|

| |

2) “Nutan” Mango Harvester |

|

|

A hand tool to harvest mango fruits with pedicle |

|

Avoid jerks to the branches

|

|

No fruit drop during harvesting |

|

Capacity: 140 fruits/hr

|

|

|

| |

|

| |

3) Stubble Remover |

|

|

A hand tool to remove paddy stubbles |

|

Suitable for digging field |

|

|

| |

|

| |

4)“Ankur” Toothed Spade |

|

|

A multipurpose hand tool for preparation of rings and basin, digging, seed beds, ridges and furrows, irrigation channels, making of trenches and removing weeds along with root system

|

|

|

| |

|

| |

5)"Amar” Loranthus Cutter |

|

|

The branches affected by loranthus are easily cut from base |

|

Avoid splitting of branches

|

|

|

| |

|

| |

6) “Swastik” Groundnut Hoe

|

|

|

A manually drawn implement for earthing up operation in groundnut crop |

|

Spreads soil evenly on root system of crop |

|

Easy to handle and save the time. |

|

|

| |

|

| |

7) Coconut Dehusker

|

|

|

Foot rest for stability and support

|

|

Coconut husk separated by giving 2-4 peripheral cuts of the blade by operating handle, Capacity: 50-60 coconut/hr

|

|

|

| |

|

| |

8) “Sulabh” Contour Marker

|

|

|

Low cost equipment for levelling

|

|

Suitable for vertical and horizontal interval upto 30 cm and 6 m respectively |

|

|

| |

|

| |

9) Cono Weeder

|

|

|

Manually hand operated efficient for weeding in paddy field (Low land condition) |

|

Green manuring crop and weeds are cut into pieces which helps in early conversion into organic fertilizers |

|

|

| |

|

| |

10) Japanese Weeder |

|

|

Manually operated and useful for weeding in paddy field (Low land condition) |

|

Green manuring crop and weeds are cut into pieces which helps in early conversion into organic fertilizers

|

|

Float prevent weeder from sinking |

|

|

| |

|

| |

11) Dryland Weeder

|

|

|

Manually hand operated efficient for weeding in Dryland |

|

Better grip and balanced |

|

|

| |

|

| |

12) “CAET” Cashew Cutter |

|

|

Useful to cut dry cashew nuts |

|

|

| |

|

| |

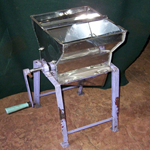

13) “Vipul” Cashewapple Juice Extractor |

|

|

Useful to extract cashew apple juice from ripe cashew apples for preparation of ready to serve, sharbats, nectar etc.

|

|

|

| |

|

| |

14) Arecanut Dehusker |

|

|

Suitable for small farmers |

|

Manually operated, suitable for medium size nuts |

|

Capacity : 4-6 Kg/hr, Breakage: 10-12 %, Unhusked arecanut : 3-5%, Efficiency of machine : 85 % |

|

|

| |

|

| |

15) Pankaj Puddler

|

|

|

A bullock drawn implement for puddling of rice field More efficient for churning of soil |

|

Give quality puddling |

|

Efficient in destruction of weedsSave labour and time. |

|

|

| |

|

| |

16) Cashewnut Desheller |

|

|

Manually operated useful for deshelling of steam roasted cashew nuts, arrangement for adjusting the distance between two cutting jaws |

|

|

| |

|

| |

17) Inverted Chain Conveyor Type Paddy Thresher

|

|

|

Gives full length Paddy straw without loss |

|

Suitable for small and medium farmers |

|

Inverted chain conveyor is durable and requires less maintenance |

|

Threshing efficiency 98.53% |

|

|

| |

|

| |

18) Hand Operated Arecanut Scarifier |

|

|

Suitable for scarifying arecanut |

|

Capacity 25 to 30 kg/hr |

|

Better acceptability of nuts in terms of colour, texture and taste |

|

50% time saving than existing scarifying method |

|

|

| |

|

| |

19) Green Cashewnut Sheller |

|

|

Suitable for shelling green cashewnut |

|

Recovery is good if cashewnuts are shelled one day after harvest |

|

Shelling capacity 120-140 nuts/hr (2 to 2.25 kg) |

|

Shelling Efficiency 98%, full kernel recovery 95%

|

|

|

| |

|

| |

20) Zero Till Drill |

|

|

Useful for sowing beans after harvest of Kharif rice |

|

Two labours are required for operating machine

|

|

Capacity 0.15 ha/hr, efficiency 71%, depth of sowing 3.7 cm |

|

|

| |

|

| |

21) Konkan Multipe Fruit Harvester |

|

|

A handtool to harvest cashew, mango, kokum etc. fruits without injuries to fruit |

|

Provision of adjusting length of handle |

|

Capacity to harvest 141, 333 and 46.06 kg/day of cashewnut, mango kokum respectively. |

|

|

| |

|

| |

22) Tractor Mounted Hydraulic Elevator |

|

|

Suitable for coconut harvesting |

|

Automatic lifting mechanism and provision of bucket to stand operator and to keep fruits. |

|

Easy movement up to 1800 to both sides of tractor, at a time four trees are covered. |

|

Maximum lifting height 12 m. |

|

|

| |

|

| |

23) “Atul” Fruit Harvester |

|

|

A hand tool to harvest sapota, kokum, ber, kagzi lime and similar fruits easily |

|

No injuries to fruits, Nylon net for collecting fruits |

|

Requirement of wooden handle suitable to tree height, Capacity : 600 fruits/hr |

|

|

| |

|

| |

24) Self propelled reaper for harvesting of paddy |

|

Self propelled reaper was developed for harvesting of paddy. The cutter bar width was 1.2 m. It was decided to have power source as 3 hp petr5ol start kerosene run engine. The reaper was designed to have operating speed as 2 to 2.5 km/h. Gear box and chain and sprocket type power transmission arrangements were used. The gear box was splitted in two units so as to have proper balancing and less stress on arms while operating. The weight of the developed reaper was 225 kg. The dog clutch was provided for turning.

The field performance as well as ergonomic evaluation of developed self propelled reaper was carried out

- The field capacity was about 1 ha/day

- The time required to cover one has was 7 h.

- The fuel consumption was about 1 1/h

- The height of stubble was about 10 cm

- The average working heart rate was 141 beats/min. The average work pulse was 43.3 beats/min and noise level was 85.6 dB (A)

|

|

| |

|

| |

25) Pedal operated arecanut dehusker |

|

Pedal operated arecanut dehusker was developed based on ergonomical and mechanical considerations. Dehusking mechanism having rubber beaters was developed for dehusing of dried arecanut fruits. It was operated by pedal using bicycle mechanism. The machine dimensions such as hopper height, saddle height, handle diameter and length etc. were designed using the relevant anthropometric data/ The peripheral speed of dehusking drum was optimized as 7 m/s with 15 kg/ha feed rate. The pedaling rate was optimized as 60 rpm with power requirement as 75 W. The developed prototype of pedal operated arecanut dehusking was ergonomically and mechanically evaluated.

-

The mean working heart rate, oxygen consumption rate and energy expenditure rate were 127 (± 8.4) beats/min, 1.3 (± 0.1) lit/min and 27 (± 2.79) kJ/min, respectively.

- The average dehusking efficiency and kernel breakage for pedal operated arecanut dehusker at 7 m/s peripheral speed and 15 kg/ha feed rate were 96.6 per cent and 6.9 per cent, respectively.

- The dehusking capacity for pedal operated dehusker was 9.8 kg/h, which was 2.7 times more than that of by traditional method

- Dehusking cost of recanut with traditional method and pedal operated dehusker was Rs. 5.1/kg and Rs. 3.7/kg, respectively

- The dehusking cost of arecanut by pedal operated dehusker was 27.5 per cent less as compared to traditional method.

|

|

| |

|

| |

26) Power operated arecanut dehsuker |

|

Power operated dehusker was developed for increasing the dehusking capacity and reducing drudgery. Dehusking mechanism having rubber beaters was developed for dehusking of dried arecanut fruits. One horse power single phase electric motor was used as power source. Belt pulley type power transmission was used. A simple hopper with flutted wheel type metering mechanism having two fruits was developed. The space of each flute is sufficient to accommodate 2 to 3 arecanut fruits. The capacity of hopper was sufficient to store 8 to 10 kg of arecanut dried fruits. The feeding rate of dried arecanut from 30 kg/ha to 15 kg/h could be altered by just closing and opening of flutes.

- In case of power operated arecanut dehusker, average dehusking efficiency and kernel breakage ast 7 m/s peripheral speed and 20 kg/h feed rate were 98.1 per cent and 9.9 per cent, respectively.

- The dehusking capacity for power operated dehusker was 13 kg/h, which was 3.6 times more than that of by traditional method.

- Dehusking cost of arecanut with traditional method and power operated dehusker was Rs. 5.1/kg and Rs. 1.9/kg, respectively.

- The dehusking cost of arecanut by power operated dehusker was 63.5 per cent less as compared to traditional method.

|

|

| |

|

| |

27) Foldable Coconut Dehusker |

|

It is recommended to use Dr.BSKKV developed foldable coconut dehusker having detachable handle for better performance and easy handling.

|

|

| |

|